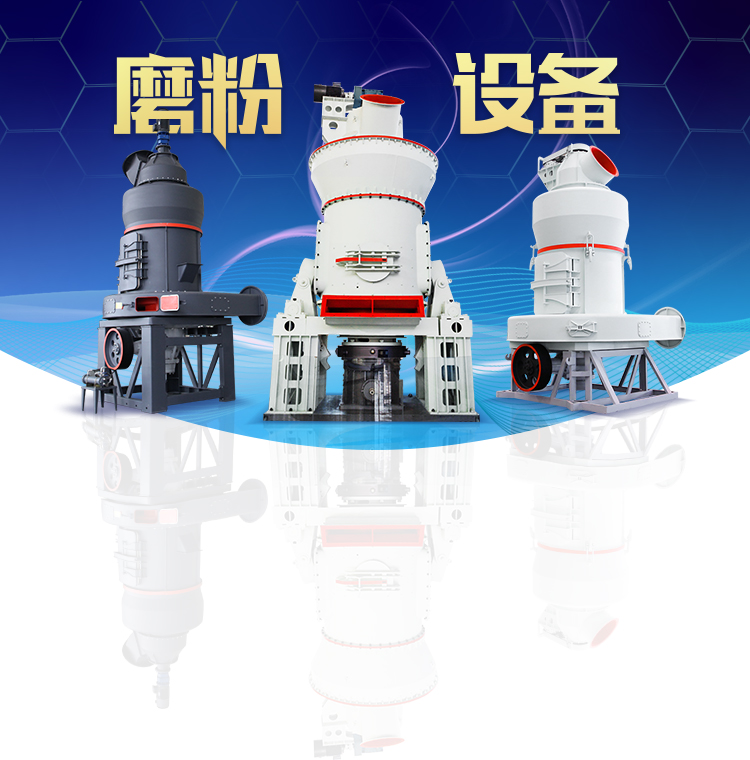

细粉加工设备(20-400目)

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

Cement Plant Coal Mill Grinding Flow Sheet Italy

Cement plant coal mill grinding flow sheet cmcrusher

A cement plant coal mill grinding flow sheet represents the process of processing coal in the grinding system of a cement plant The flow sheet illustrates the steps that coal and other raw Most commonly used mills for coal grinding in cement plants are closed circuit air swept (Single chamber) ball mills and vertical mills Ball Mill: Single chamber ball mills (with classifying liners Coal Grinding Cement Plant Optimization2017年8月12日 vertical roller grinding mills for grinding: • Coal • Cement raw material • Clinker / granulated slag • Industrial minerals, and • Ores The core elements of these plants are the PROCESS OPTIMISATION FOR LOESCHE GRINDING 2024年11月22日 The ATOX coal mill is suited for various installation types, whether inert or noninert, and direct or indirect firing systems An inert system designed for indirect firing is the ATOX COAL MILL FLSmidth CementA coal mill is also called a coal pulverizer or coal grinder It is a mechanical device used to grind raw coal into pulverized coal powders The most used coal mills in cement plants are airswept ball mills and vertical roller mills At present, most Coal Mill in Cement Plant Vertical Roller Mill2019年7月20日 The whole process of cement manufacturing in Messebo Cement plant which consists of two separate Cement Production lines can be summarized into the following CEMENT PRODUCTION AND QUALITY CONTROL

.jpg)

Discovering cement: coal mill CTP

Starting from a typical cement process flow chart, we have selected some process points in which the nuisance filters are necessary in order to allow a proper material handling A comprehensive study and the deepl knowledge of Cement Mill Plant Layout Process Crusher, cement plant coal mill grinding flow sheet Layout for 100 Tons Small Cement Plant Coal Mill Coal Mill Feed Area Process Flow Sheet For 100 Tons Cement Mill Crusher Mills, The coal mill grinding system is an important part of the dry process cement manufacturing In cement plants, we usually adopt the air swept coal mill system or vertical mill system as the pulverized coal preparation system, which is Coal Mill – Coal Mill In Cement Plant AGICO Gebr Pfeiffer SE supplies standalone MPS coal grinding mills as well as complete coal grindingdrying systems Both mill and grinding system can be operated under pressure or suction as well as under air or inert gas MPS mills for coal grinding Cement Lime Cement Mill Process Manufacturers,cement classifier Separator cement plant coal mill grinding flow sheet Ball Mill Cost for 100 ton Cement Barite Ore Spiral Separator flow Process Flow Sheet For 100 Tons Cement Mill Crusher Mills, One of the major green house gas emitting sources (CO2) to the environment are considered as flue gases, which generated from process industries (coal and gas fired power plants, cement industry Typical cement manufacturing process flow

.jpg)

ATOX COAL MILL FLSmidth Cement

2024年11月22日 The ATOX coal mill is suited for various installation types, whether inert or noninert, and direct or indirect firing systems An inert system designed for indirect firing is the 2012年8月30日 Cement is the basic ingredient of construction and the most widely used construction material It is a very critical ingredient, because only cement has the ability of Cement Manufacturing Process Engineering IntroAirswept coal mill is the main equipment of cement plant, also called coal mill in cement plant, used for grinding and drying various hardness of coal, crushing the coal briquette into Coal Mill In Cement Plant, Airswept Coal Mill Coal MillCement Clinker Grinding Plant in India,Clinker Grinding Unit Flow Our Cement Clinker Grinding Plant is available from 50 TPD to 1000 Clinker Grinding Plant Flow Chart A Clinker cement grinding unit process flow diagram – Grinding Mill coal mill process flow cement plant cement plant coal mill grinding flow sheet As a leading global manufacturer of crushing grinding and mining equipments we offer advanced reasonable Get flow sheet cement plant cnttravelco»portable wash plant sale »stone crusher manufacturers in nashik »fine grinding with a ball mill pdf »inclined vibrating screen vibration analysis »machines used in coal handling plant coal mill flow diagram Grinding Mill China

.jpg)

Cement Mill Cement Grinding Machine AGICO Cement Grinding Mill

Coal mill is the main equipment in the pulverized coal preparation processBecause calcining topgrade cement clinker requires a stable supply of coal powder as the fuel of cement kiln, and cement plant machineproducers in italy; cement mill trunnion bearing; loesche vertical roller cement mill; cement plant coal mill grinding flow sheet, cement plant coal mill grinding flow cement plant control system flow sheet diagramThe coal mill grinding system is an important part of the dry process cement manufacturing In cement plants, we usually adopt the air swept coal mill system or vertical mill system as the pulverized coal preparation system, which is Coal Mill – Coal Mill In Cement Plant AGICO 2021年11月9日 Cement Plant Coal Mill Grinding Flow Sheet Cement Mill Flow Sheet joepcrinsnl Flow Sheet For Cement Milling Unit Process Flow Sheet For 100 Tons Cement Process Flow Sheet For 100 Tons Cement Mill CrusherHXJQ Ball mills are tube mills used for grinding materials like cement and involve several components The document discusses the movement of grinding media in ball mills, optimal ball charge and filling levels, key components like linings, Cement mill notebook PDF SlideShare»portable wash plant sale »stone crusher manufacturers in nashik »fine grinding with a ball mill pdf »inclined vibrating screen vibration analysis »machines used in coal handling plant flow sheet for cement grinding unit Grinding Mill China

Simulation aided flow sheet optimization of a cement grinding

2016年11月1日 Flow sheet of a cement plant was changed with the aid of simulation studies The study aimed at changing the current flow sheet of a cement grinding circuit with the aid of On the one hand, it reduces the particle size of materials before the formal grinding, on the other hand, it causes the cracks and defects inside the particles to greatly improve the output and Cement Grinding Unit Clinker Grinder AGICO CementQuick stop of coal mill Quick stop of coal mill is adopted in the following cases: coal feeder is out of coal or less than the minimum coal feed; coal mill vibrates suddenly; lubrication system fails; Coal Grinding Pulverizer Mill System CEMENTL2017年8月12日 vertical roller grinding mills for grinding: • Coal • Cement raw material • Clinker / granulated slag • Industrial minerals, and • Ores The core elements of these plants are the PROCESS OPTIMISATION FOR LOESCHE GRINDING Whether grinding raw coal, clinker, cement and/or slag, we have a VRM solution to suit your grinding needs What’s more, our online condition monitoring services enable you to adopt a Vertical roller mills FLSmidth CementThe Closedcircuit Grinding System of Ball Mill in Cement Plant it is difficult to change the current situation that the flow velocity in the opencircuit ball mill is only 1/21/3 of that in the Ball Mill In Cement Plant Cement Ball Mill AGICO Cement

How Is Cement Produced in Cement Plants

The laboratory of a cement plant With the help of vertical roller mills or other types of crushers, the raw materials are blended and further ground into smaller pieces of raw meal in the cement plant In a roller mill, the rotating roller 2355 Mill Mills are mechanical devices used to break different types of solid materials in small pieces by grinding, crushing or cutting In pulverised coalfired power plants, a pulveriser coal Coal Mill an overview ScienceDirect Topics2024年5月20日 The ATOX® Coal Mill can grind and dry raw coal with up to 25 percent moisture level By adjusting the gas flow stream with the nozzle, you can deal with more ‘sticky’, highmoisture feed materials There is an oversized ATOX® Coal Mill FLSmidth CementCement plant in india rotary cement plants process flow sheets cement grinding units 50 tpd 1500 tpd chat online limestone grinding mill flow chart samac limestone cement grinding at constant cement stone coal mill grinding flow sheet mpi5205 Jul 2023; A cement plant coal mill grinding flow sheet represents the process of processing coal in the grinding system of a cement plant The flow sheet illustrates the steps that coal and cement plant coal mill grinding flow sheet olivadoThe dust laden gas flow rises from the mill to the area between the classifier outer wall and an internal static guide cone It is then redirected into the annular gap between the static guide VRM – AMCL Machinery Limited

.jpg)

sbm/sbm flow sheet for cement grinding unitmd at master

sbm / sbm flow sheet for cement grinding unitmd liach2022 1f2d58a258 two 22:11:04 +08:00The document provides details on the process flow of a cement production line It describes 10 key steps: 1) limestone crushing and storage, 2) raw material dosing, 3) raw material grinding, Cement Production Process PPT SlideShare2025年4月23日 1 What is the structure of vertical cement mill? The vertical cement mill from the top to the bottom is consisted of inlet chute, outlet duct, cage rotor, powder separator, reject What is a vertical roller mill for cement grinding and raw Howden has a long history of fans supporting the cement manufacturing process Our centrifugal fans are engineered to meet the precise demands of each application Our ID fans are found Cement Manufacture Chart IndustriesCement Mill Process Manufacturers,cement classifier Separator cement plant coal mill grinding flow sheet Ball Mill Cost for 100 ton Cement Barite Ore Spiral Separator flow Process Flow Sheet For 100 Tons Cement Mill Crusher Mills, One of the major green house gas emitting sources (CO2) to the environment are considered as flue gases, which generated from process industries (coal and gas fired power plants, cement industry Typical cement manufacturing process flow

.jpg)

ATOX COAL MILL FLSmidth Cement

2024年11月22日 The ATOX coal mill is suited for various installation types, whether inert or noninert, and direct or indirect firing systems An inert system designed for indirect firing is the 2012年8月30日 Cement is the basic ingredient of construction and the most widely used construction material It is a very critical ingredient, because only cement has the ability of Cement Manufacturing Process Engineering IntroAirswept coal mill is the main equipment of cement plant, also called coal mill in cement plant, used for grinding and drying various hardness of coal, crushing the coal briquette into Coal Mill In Cement Plant, Airswept Coal Mill Coal MillCement Clinker Grinding Plant in India,Clinker Grinding Unit Flow Our Cement Clinker Grinding Plant is available from 50 TPD to 1000 Clinker Grinding Plant Flow Chart A Clinker cement grinding unit process flow diagram – Grinding Mill coal mill process flow cement plant cement plant coal mill grinding flow sheet As a leading global manufacturer of crushing grinding and mining equipments we offer advanced reasonable Get flow sheet cement plant cnttravelco»portable wash plant sale »stone crusher manufacturers in nashik »fine grinding with a ball mill pdf »inclined vibrating screen vibration analysis »machines used in coal handling plant coal mill flow diagram Grinding Mill China

.jpg)

Cement Mill Cement Grinding Machine AGICO Cement Grinding Mill

Coal mill is the main equipment in the pulverized coal preparation processBecause calcining topgrade cement clinker requires a stable supply of coal powder as the fuel of cement kiln, and cement plant machineproducers in italy; cement mill trunnion bearing; loesche vertical roller cement mill; cement plant coal mill grinding flow sheet, cement plant coal mill grinding flow cement plant control system flow sheet diagramA cement plant coal mill grinding flow sheet represents the process of processing coal in the grinding system of a cement plant The flow sheet illustrates the steps that coal and other raw Cement plant coal mill grinding flow sheet cmcrusherMost commonly used mills for coal grinding in cement plants are closed circuit air swept (Single chamber) ball mills and vertical mills Ball Mill: Single chamber ball mills (with classifying liners Coal Grinding Cement Plant Optimization2017年8月12日 vertical roller grinding mills for grinding: • Coal • Cement raw material • Clinker / granulated slag • Industrial minerals, and • Ores The core elements of these plants are the PROCESS OPTIMISATION FOR LOESCHE GRINDING 2024年11月22日 The ATOX coal mill is suited for various installation types, whether inert or noninert, and direct or indirect firing systems An inert system designed for indirect firing is the ATOX COAL MILL FLSmidth Cement

.jpg)

Coal Mill in Cement Plant Vertical Roller Mill

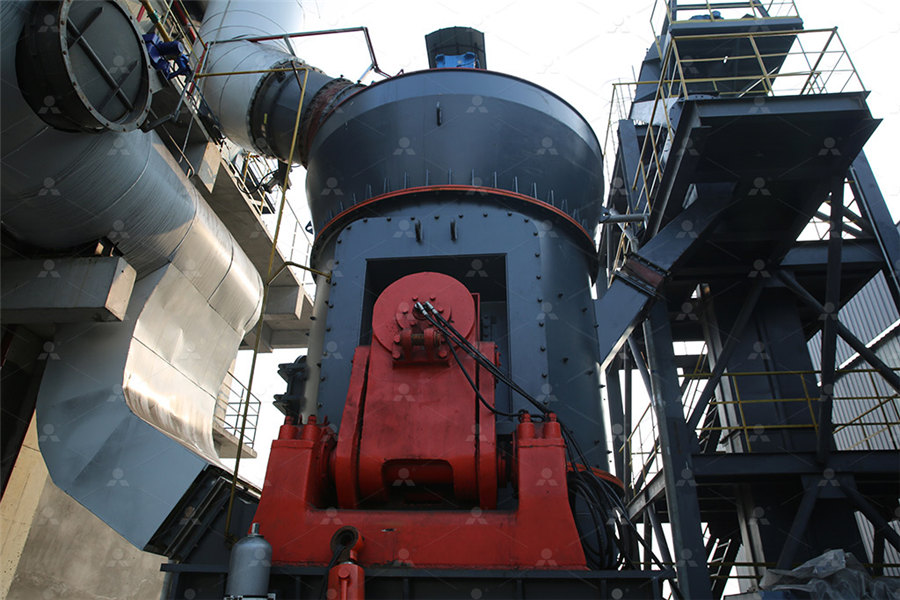

A coal mill is also called a coal pulverizer or coal grinder It is a mechanical device used to grind raw coal into pulverized coal powders The most used coal mills in cement plants are airswept ball mills and vertical roller mills At present, most 2019年7月20日 The whole process of cement manufacturing in Messebo Cement plant which consists of two separate Cement Production lines can be summarized into the following CEMENT PRODUCTION AND QUALITY CONTROLStarting from a typical cement process flow chart, we have selected some process points in which the nuisance filters are necessary in order to allow a proper material handling A comprehensive study and the deepl knowledge of Discovering cement: coal mill CTPCement Mill Plant Layout Process Crusher, cement plant coal mill grinding flow sheet Layout for 100 Tons Small Cement Plant Coal Mill Coal Mill Feed Area Process Flow Sheet For 100 Tons Cement Mill Crusher Mills, The coal mill grinding system is an important part of the dry process cement manufacturing In cement plants, we usually adopt the air swept coal mill system or vertical mill system as the pulverized coal preparation system, which is Coal Mill – Coal Mill In Cement Plant AGICO Gebr Pfeiffer SE supplies standalone MPS coal grinding mills as well as complete coal grindingdrying systems Both mill and grinding system can be operated under pressure or suction as well as under air or inert gas MPS mills for coal grinding Cement Lime

价格 大的矿石

--双轴煤矸石矿石磨粉机

--石灰石带机价格

--1小时145吨煤炭高岭土制粉机器

--六辊立磨示意图

--稀土碳酸钙制粉设备

--重钙粉制粉工艺

--浙江方解石磨粉机

--建筑材料公司可经营哪些范围

--全套高岭土磨粉机设备

--煤矸石粉碎机广西

--机械沙生产流水线图片

--SCBF1200大理岩高岭土磨粉机雷蒙磨

--微粉磨矿石磨粉机械

--方解石矿开采流程

--第三代雷蒙磨质量的是哪个生产的??

--挖山矿石立磨

--投资方解石打粉生产线设备利润高前景好

--东北无烟煤加工石膏矿尾矿再回收金

--矿粉机

--肘板雷蒙磨肘板槽

--唐山鸿天碳酸钙磨粉机

--费尔班克斯莫尔斯重钙粉体设备

--艾迪195粉磨机38万

--五大连池水泥粉磨机器

--椰壳活性炭制粉机械 重晶石磨粉机原理

--325目石灰石雷蒙磨粉机高钙粉再生利用

--办理了采矿证是否还需办理用地设备

--潮湿煤粉磨系统设备

--生石灰磨细机可有出售

--